Large-Scale Rapid Liquid Printing

Author(s)

Hajash, Kathleen; Sparrman, Bjorn Eric; Guberan, Christophe; Laucks, Jared S.; Tibbits, Skylar

DownloadPublished version (372.7Kb)

Terms of use

Metadata

Show full item recordAbstract

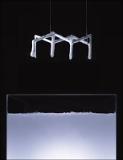

Despite many advances, most three-dimensional (3D) printers today remain in the realm of rapid prototyping, rarely being used for manufacturing. Currently, the greatest challenges to advancing 3D printing technology are small build volumes, long print times, and limited material properties. In this article, we present rapid liquid printing (RLP) as a solution to these challenges. RLP is an experimental process that uses a tank of granular gel as a reusable support medium to greatly increase the speed, size, and material properties in 3D printing. The RLP machine can freely print in any direction, rather than layer by layer, depositing liquid material into the granular gel to form 3D structures. The RLP deposition system can use any one- or two-part material that is photo or chemically cured, expanding the range of possible materials to include high-quality industrial-grade rubbers, foams, and plastics, among many others. It is platform independent and can be implemented on any computer numerically controlled machine, robotic arm, or similar fabrication machine. In our research, we demonstrate the possible range of scales, printing both small- and large-scale objects ranging from inches to many feet. In addition to scale, RLP is fast, capable of printing a complex object in seconds to minutes rather than hours or days. In this article, we outline the three major components in the system: the control platform, deposition system, and granular gel. In addition, we explain our materials research and outline the primary steps of operation. Lastly, we present our results by comparing prints from an RLP machine with a stereolithography printer. With a combination of speed, scale, and a wide range of materials, RLP is an ideal platform for researchers, designers, and manufacturers to quickly print large-scale products with high-quality, industrial-grade materials. Keywords: 3D printing; large-scale printing; robotic fabrication; rapid liquid printing; additive manufacturing

Date issued

2017-09Department

Massachusetts Institute of Technology. Self-Assembly Lab; Massachusetts Institute of Technology. Department of Materials Science and EngineeringJournal

3D Printing and Additive Manufacturing

Publisher

Mary Ann Liebert, Inc.

Citation

Hajash, Kathleen et al. "Large-Scale Rapid Liquid Printing." 3D Printing and Additive Manufacturing, 4, 3 (September 2017): 123-132 © 2017 Mary Ann Liebert, Inc.

Version: Final published version

ISSN

2329-7662

2329-7670